..........

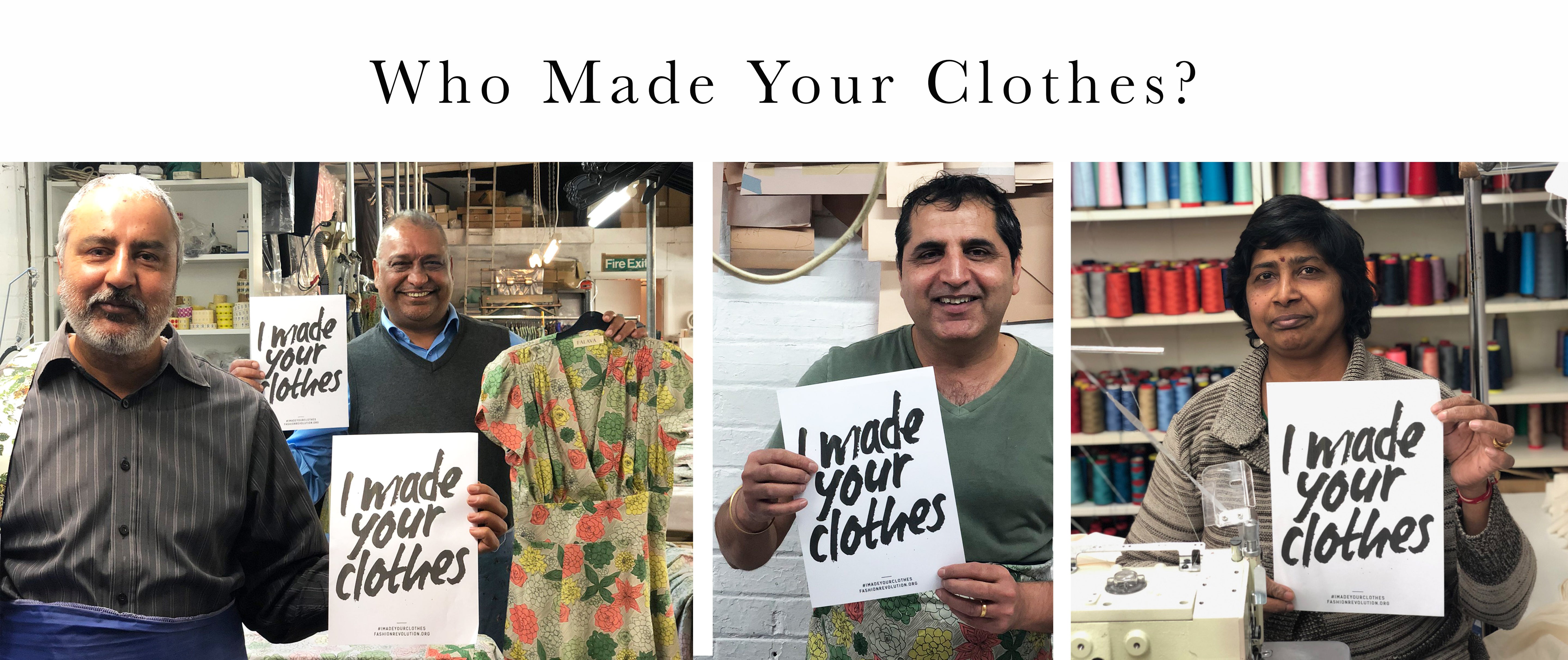

Do you ever think about who made your clothes?

In this post we will be showing you the people, places and processes involved in each step of our manufacturing process.

We are passionate about the welfare of the people behind our clothes - every step of the way. We are proud to state that all of the people who make our clothes in our UK factory and in our Turkish factory (where we produce our knitwear) receive the living wage or higher, have a 1 hour lunch break each day, have two tea breaks a day and have dry, safe and warm working conditions.

So! Without further ado, let's begin!

S A M P L E M A C H I N E S T

Our first step after designing a dress is a visit to our sample machinist, Julie. Julie makes one of every design in a collection (in every colourway) for us. This is a really important stage as it allows us to spot any mistakes and make any improvements before the we make the items that you will be buying. We're really lucky to have Julie - she knows an awful lot about sewing and is often on hand to advise us if we want to make chnages to our design.

C U T T E R

Once we are happy with our samples, the real action begins. We work with a small family-run factory based just outside London. The first step here is to cut the cloth. Satnam is our cutter and it's his job to lay and cut out our patterns on the fabric in the most efficient way. He also has to bear in mind the direction of the printed cloth... it's no good if all the flamingos are upside down on a dress!

We are passionate about limiting waste and Satnam helps us out here by collecting all the scraps left over after cutting out. We then turn these scraps into hairties, bows, bags and our famous fabric bundles.

M A C H I N E S T S

After cutting, comes the stitching! Our factory has a small team of expert machinists who carefully sew each garment together. Each machinist will work through one step for many of the same items at once. For example, a machinist might spend a morning sewing on sleeves to 20 dresses of the same print and style. This is the most efficient way of working. Luckily, we don't ever make terribly many of any of our dresses so there is quite a lot of variety for our machinists!

Once the dress is sewn, it needs to be pressed. Anyone who has made their own clothes before will know that pressing a garment transforms it. It is a vital stage of the process in order to get a beautifully finished product. Rakesh and Paul are our factory's Pressers. They make a merry team and do a really great job.

P A C K I N G & W A R E H O U S E

And finally comes the packing. Each item will be carfefully folded and then placed into one of our clear, biodegradable bags. Items are then sent up to our warehouse in Yorkshire (where Palava was founded and we used to be based) and handed over to our dispatch team - Katie and Zoe. These girls are just great. They carefully package your items in our iconic brown delivery bags when you place an order, keep an eye on stock levels and make sure that the your new garment reaches you in ship-shape condition.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.